Tip: Start typing in the input box for immediate search results.

working with PM

Overview

sfddfds

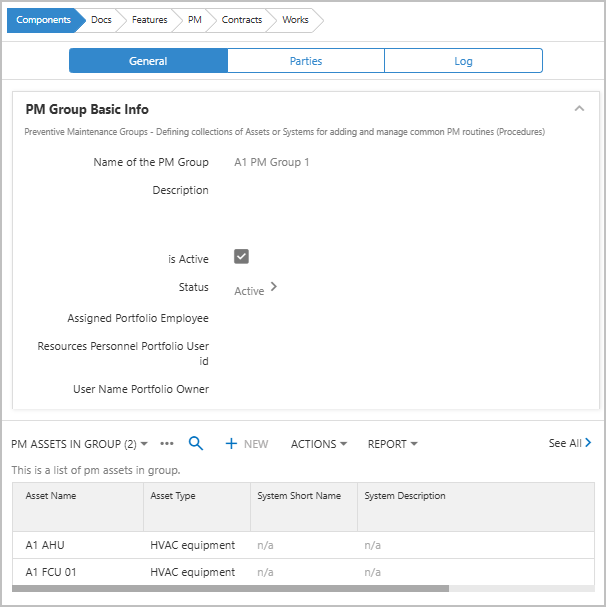

PM Groups (Assets or Systems)

Preventive Maintenance Groups – Defining collections of Assets or Systems for adding and manage common PM routines (Procedures). This refers to a collection of related assets or equipment that share a common maintenance schedule, procedures, or servicing requirements. These groups help streamline facility management by organizing assets based on their maintenance needs, ensuring efficient scheduling, resource allocation, and compliance with maintenance standards.

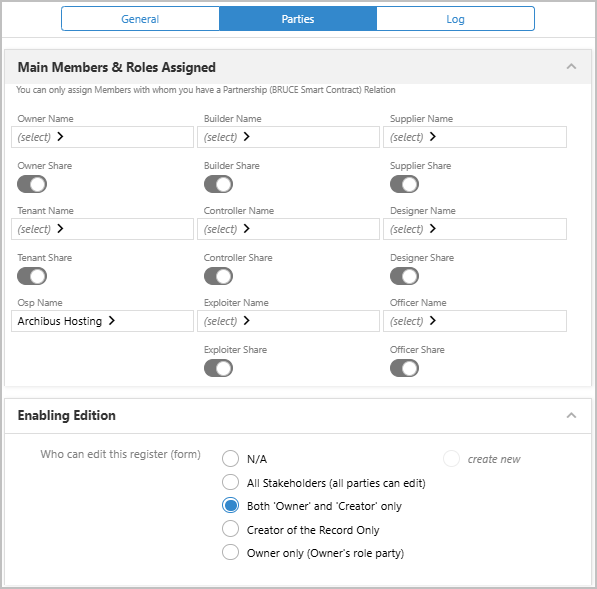

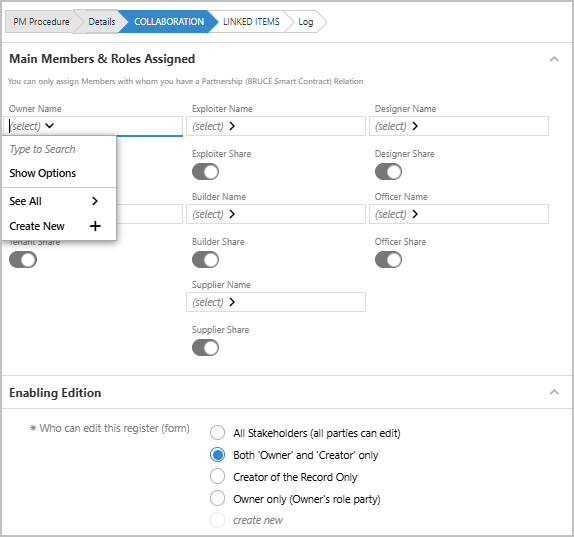

Parties – Main Members

You can only assign Members with whom you have a Partnership (BRUCE Smart Contract) Relation

PM Schedules

Planned Works (Scheduled works)

wre

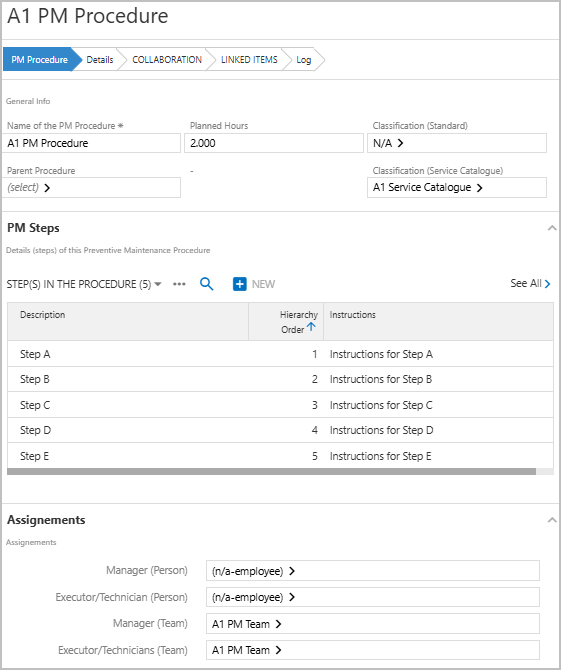

PM Procedures

A Preventive Maintenance (PM) Procedure is a systematic approach to inspecting, servicing, and maintaining equipment to prevent unexpected failures and extend its lifespan. It involves scheduled checks, lubrication, part replacements, and performance testing based on manufacturer guidelines and operational needs. A well-structured PM procedure reduces downtime, improves efficiency, and ensures workplace safety.

Collaboration

You can assign members only if you have an established partnership with them through the Bruce Smart Contract relationship. This ensures that tasks, roles, or responsibilities are delegated exclusively to trusted and verified partners, maintaining security, compliance, and seamless collaboration within the system.

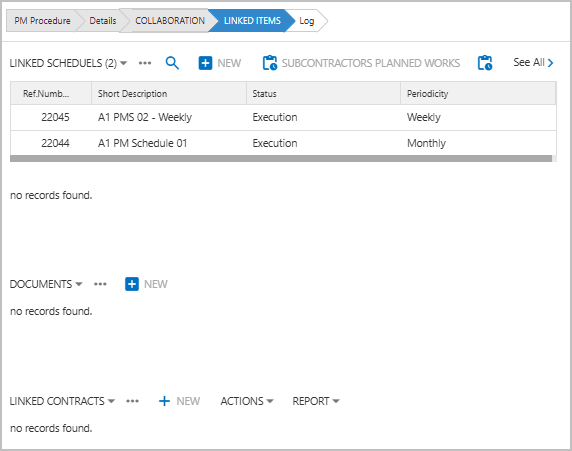

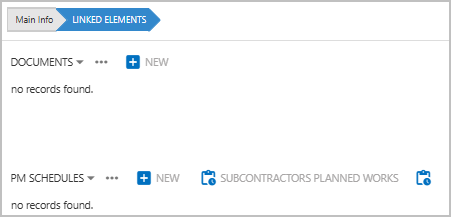

Schedules, Documents, Contracts etc. can be linked

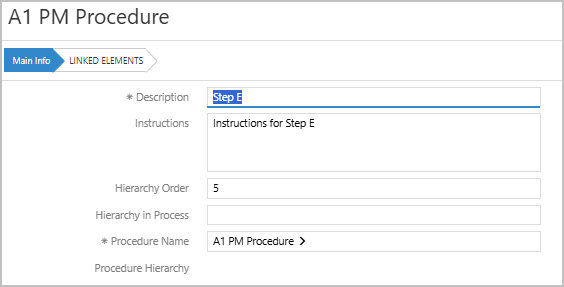

PM Steps

The Preventive Maintenance (PM) Steps are essential actions that ensure the effectiveness of a PM procedure. These steps typically include inspection, where equipment is checked for wear and tear; scheduling, which sets maintenance intervals based on usage and manufacturer guidelines; servicing, involving cleaning, lubrication, and minor repairs; replacement, where worn-out parts are changed to prevent failures; and testing, to confirm proper functionality after maintenance. Following these steps systematically helps extend equipment lifespan, improve efficiency, and minimize unexpected downtime.

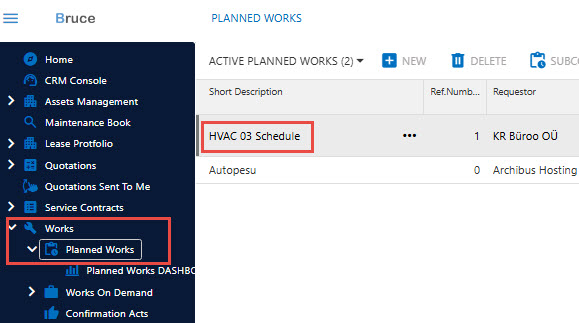

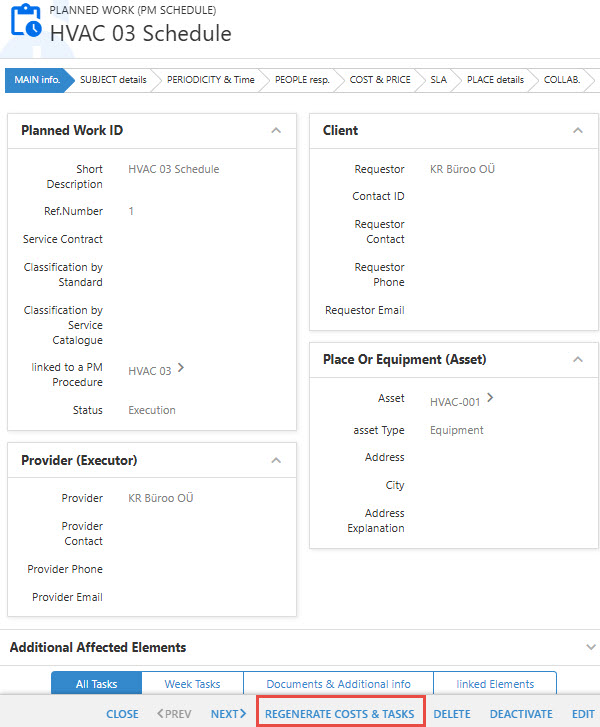

Regenerate Task

The Task are automatically generated every midnight. However, the Task can be forced generated from the following option:

Go to “Planned Works” then select the Schedule for which the Task needs to be forced generated. The click on “REGENERATE COST & TASKS”.